KraussMaffei @K2025

Düsseldorf, October 8th – 15th, Hall 15, Booth C24

Performance. Perfected. For you.

20% more compact, 20% more efficient, 100% future-ready

The new generation of the all-electric PX series will make its debut at K 2025 – with clamping forces from 800 to 2,000 kN. Even more space-saving, productive, and sustainable.

Your benefits at a glance:

- Highest energy efficiency thanks to modern drive technology with energy recovery

- Maximum precision through consistent shot weights and fast cycle times

- Compact, flexible design for integrated cells and optimal use of space

More performance, more operating comfort

The new MC7 control system offers maximum performance, intuitive operation, and top-level IT security. Thanks to its modern architecture, it is ideally suited for tomorrow’s connected production.

Your benefits at a glance:

- Intuitive, user-friendly interface

- Cybersecurity-ready in accordance with the Cyber Resilience Act (CRA)

- Powerful hardware and software platform

- Easy integration into connected systems

Revolutionized processing of glass fibers

The new Chopped Fiber Processing (CFP) technology enables direct compounding of chopped glass fibers and polypropylene – economical, efficient, and material-saving. The patented screw geometry ensures optimal melting and homogeneous mixing.

Your benefits at a glance:

- High flexibility and significant cost advantages with consistent high part quality

- High-quality, fiber-reinforced parts with optimal material utilization

- Retrofit-compatible with all KraussMaffei series of injection molding machines

- ROI – lass than one year

Greater efficiency. Less effort. Premium quality - straight from the factory.

ColorForm combines injection molding and surface finishing in a single process step. The result: a scratch-resistant premium surface without additional coating.

Your benefits at a glance:

- One process, one machine: maximum time savings for painted components

- Greater efficiency: Fewer process steps, easier handling

- Design without limits: new materials and surfaces

- Sustainable production: No spray painting means fewer emissions

- Everything from a single source: Turnkey complete solution from KraussMaffei

Together with its partner Leonard Kurz, KraussMaffei is going one step further at K 2025: a newly developed, mold-integrated film thermoforming concept allows a design film to be applied directly in the mold. The result is a high-gloss, scratch-resistant, and stylish surface that is ideal for demanding applications such as front headlights.

Visit us here: GXW 650 ColorForm live at our partner booth Leonard Kurz (Hall 5, booth A19)

Your benefits at a glance:

- 3-in-1 process: injection molding, decoration, and protective coating in a single cycle

- Perfect design: high-quality appearance thanks to precisely positioned design film

- Maximum protection: PUR top layer protects against UV yellowing and stone chips

- Greater efficiency: no subsequent painting, less handling, shorter cycle times

Efficient, economical, resource-saving

Together with BASF, RAMPF, and Remondis, KraussMaffei is developing an industrial recycling process for PU insulation foams from old refrigerators. The continuous extrusion process enables chemical recovery even with heavily contaminated regrind.

Your benefits at a glance:

- High tolerance to contamination (up to 30% foreign materials)

- Cost-effective alternative to batch processing

- Directly usable rPolyol for new PUR applications

- No incineration, more circular economy

- Flexible use across various applications

Proven quality with digital capabilities

KraussMaffei continues to advance its proven metering machine series on the path to digitalization. This includes essential features that make working with the machine even easier and more intelligent.

Your benefits at a glance:

- New HMI: more intuitive and user-friendly operation with standardized visualization

- Sensory detection of pump wear: this is adjusted without manual intervention

- DataXplorer: live recording and evaluation of all process-relevant parameters

- Precision mixing head: further optimized mixing head design for simplified maintenance

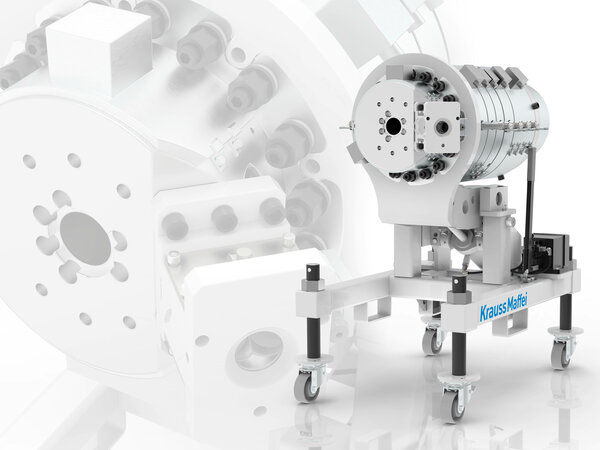

Our state-of-the-art compounding solutions are based on the ZE BluePower series and impress with reliability, energy efficiency, and cost-effectiveness – because they are designed to deliver peak performance consistently.

Highlights @K 2025

Whether for developing new materials or the productive use in operations, the new generation of our BluePower twin-screw extruders offers numerous advantages.

Your benefits at a glance:

-

Improved operation and greater energy efficiency

-

Digital networking via the ppC control system (pioneer processControl)

-

Optimized price-performance ratio and shorter delivery times

Top performance in throughput, product quality, process reliability, and service are our standard. Benefit from the modular machine concept, which can be configured and expanded individually according to your requirements.

Your benefits at a glance:

-

Screw diameters up to 400 mm for industrial large-scale applications

-

Effective degassing through a larger diameter ratio (D/d ratio of 1.65)

-

Lower screw speeds at constant throughput thanks to a torque density of up to 16 Nm/cm³ and variable speed drive

Live presentations at our booth:

-

Direct Compounding: Multi-technology solutions from a single source

-

Compounding beyond 2025: Twin-screw extruders optimized for process engineering

-

New ZE Petrochemical: The most advanced large-scale twin-screw extruder series

-

ENK: Energy-efficient manufacturing of plastic components

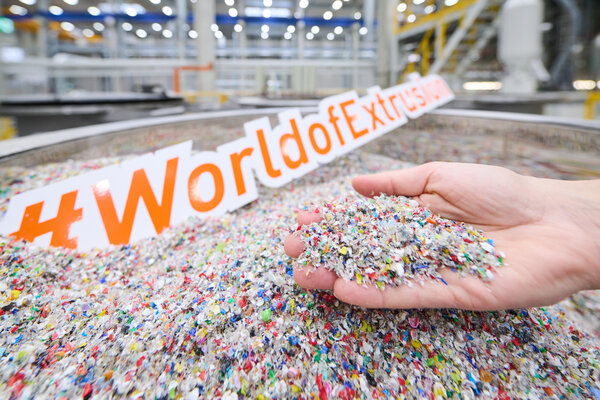

From bottle-to-bottle PET recycling to material preparation for chemical processes – as an innovation driver in the circular economy, KraussMaffei Extrusion offers forward-looking solutions for all forms of recycling.

Your benefits at a glance:

-

Over 25 years of experience

-

Over 500 kta capacity in advanced recycling processing

-

Single screws with diameters up to 400 mm

Live presentations at our booth:

- Chemical recycling of polyurethane (rigid foam)

- Chemical Recycling: Extrusion technology in depolymerization and pyrolysis

- Mechanical recycling B2B: Large-scale, energy-efficient, and food-grade PET bottle recycling

- More than just filtered: Advanced mechanical recycling solutions

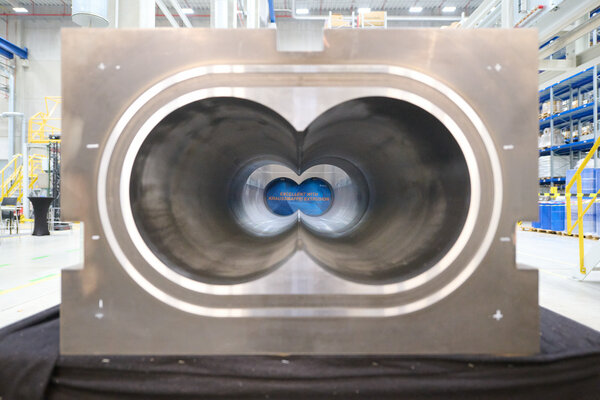

Whether pipes from 5 to 2000 mm or profiles like window frames and cable ducts – KraussMaffei Extrusion delivers complete extrusion solutions for every application. With highly efficient extruders, tools, and automation, we ensure maximum productivity, material efficiency, and quality.

Highlight @K2025

With the KM-3L RK 42-HP, KraussMaffei Extrusion sets a new global benchmark in manufacturing PVC sewage pipes.

Your benefits at a glance:

-

Safe processing of up to 100% recycled material in all three layers

-

Newly patented distribution system

-

Significant material cost savings

Live presentations at our booth:

-

Technologies and pipe heads for multilayer applications

-

The new 3-layer PVC pipe head

-

The new high-performance KME for pipe extrusion

-

Quick Switch: Dimension changes without downtime in pipe extrusion

Whether physically foamed products, films, or sheets – KraussMaffei Extrusion offers tailored extrusion systems for diverse applications. Our solutions impress with high efficiency, process stability, and excellent product quality.

Your benefits at a glance:

-

More than 40 years of experience

-

Over 250 production lines in operation

-

More than 230 large-scale trials in the lab

Live presentations at our booth:

Film/Sheet Extrusion

-

Highly filled sheets through inline compounding

-

Tailored extrusion systems for sheet production

-

Increased efficiency in sheet extrusion through inline compounding

Foam Extrusion

-

Overview of the EPS extrusion process

-

Efficient production of XPS foam boards

Learn more about various Extrusion topics with our lecture program @K2025!

Simply. Always. Fits.

The new LRXplus impresses with maximum efficiency, high precision, and particularly easy operation. Thanks to its open interfaces, it can be easily combined with injection molding machines from any manufacturer and integrates flexibly into a wide range of automation tasks.

Your benefits at a glance:

- High technical availability for reliable production processes

- Precise repeatability for consistent part quality

- Intuitive operation via the new MC7 control system

- 100% compatible with injection molding machines from other manufacturers

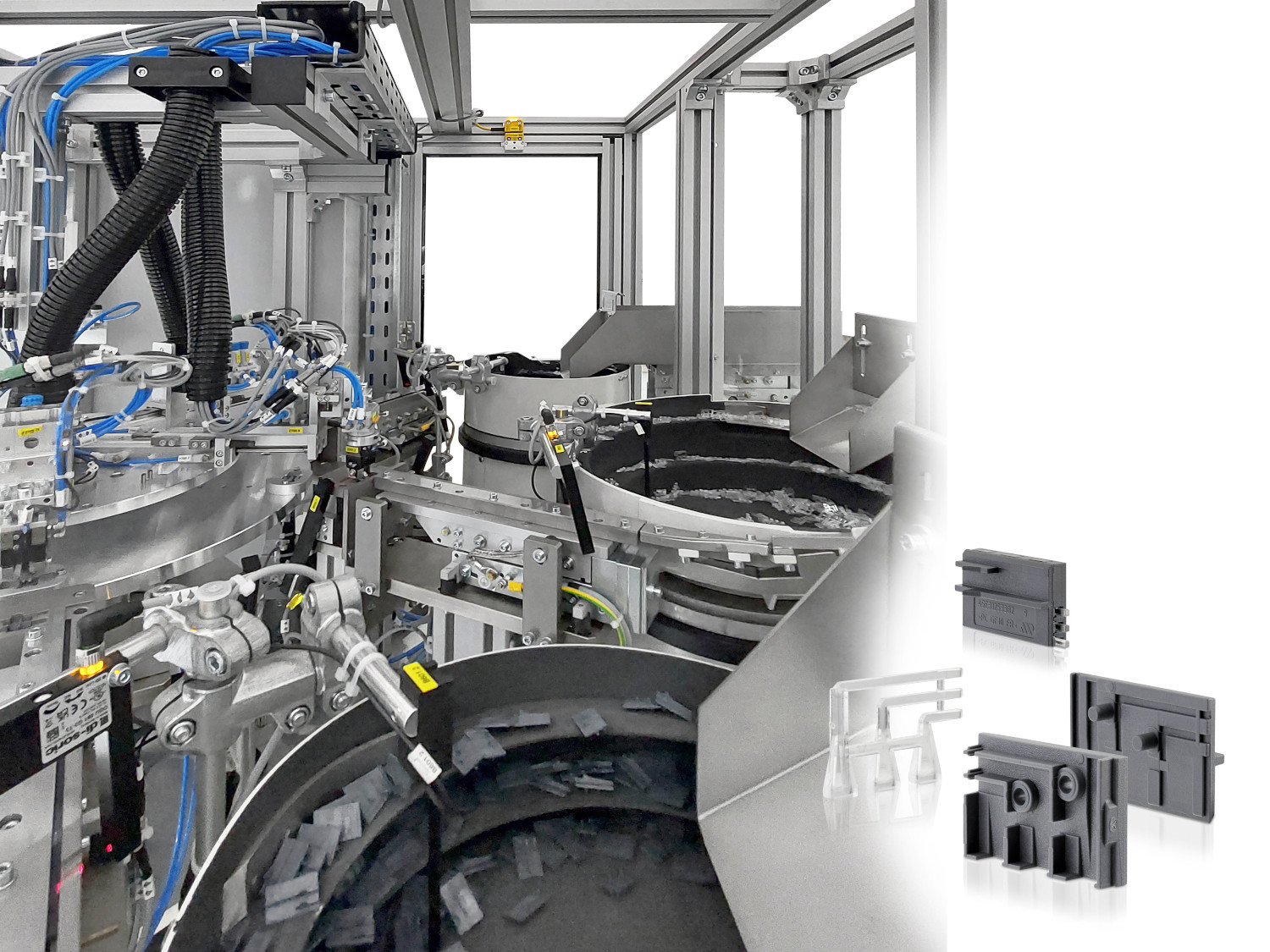

When every part fits perfectly

The new compact automation cell assembles three different plastic parts live at the K show – fully automatic, fast, and error-free.

Your benefits at a glance:

- Fully automated assembly with high process reliability

- Compact and mobile – easy to integrate into existing production lines

- Maximum precision thanks to laser measurement with 0.01 mm accuracy

- Error-free final products through automatic optical quality control and sorting

Industrial additive manufacturing with a robot

The powerPrint Flex is a compact and powerful robot solution offering maximum flexibility. It combines modular architecture, compact motors, and advanced control technology for maximum efficiency and reliability.

Your benefits at a glance:

-

Maximum flexibility at the industrial level thanks to modular design

-

Industrial high-performance extruder ensures high material throughput rates

-

Heated vacuum printing table with 16 zones enables optimum use of space

-

Continuous production thanks to intelligent feed system and dryer

-

Individual automation solutions ensure increased efficiency

3D printed thin-wall parts for automotive and whitegood applications.

Carbon fiber propellers for aerospace applications.

3D printed LearningPod – a flexible, extremely mobile (learning) booth.

Welcome to the KraussMaffei service workshop at K2025. Learn about our services in the areas of injection molding, automation, and reaction technology, and try them out for yourself.

Your machines. Your data. Anytime.

With pioneersClub, KraussMaffei's global customer platform, you can access your machines, all relevant documents, and contact our service department and order spare parts at any time.

Your benefits at a glance:

- Place a free test order now and get an exclusive goodie!

Whether you need oil coolers, heat exchangers, flange cooling, or temperature control circuits: With comprex® ToolClean, you can clean circuits using air and water—without any chemicals.

Your benefits at a glance:

- The system can be used on all systems regardless of manufacturer and impresses with proven functionality – at a new, lower price.

- With the DistributionBlock100, you can connect up to 8 circuits simultaneously and clean them automatically – saving time and maximizing efficiency.

socialProduction enables intelligent machine monitoring and team-oriented communication in plastics production – in real time, regardless of location, and proactively.

Your benefits at a glance:

-

The intelligent AI assistant provides targeted support in the daily operations – for fast problem solving and greater efficiency directly at the machine.

-

The expansion of data set management enables rapid data comparison between any two data sets. This facilitates analysis and supports targeted optimization of the setting parameters.

Visit us at our booth and discover even more services, such as the LRXplus training cell and our repair service!